To Prevent Bur Drop-off

To Prevent Bur Drop-off

If you experience any one of the following symptoms, the most likely causes are contamination and/or wear of the chuck.

- Bur drop-off

- Hard-to-pull-off bur

- Bur wobbling

Most faulty chuck troubles are caused by contamination inside the chuck due to lack of proper maintenance. To minimize the wear of chucks, pay attention to the following points.

1. Selecting a Bur

- Confirm the maximum rotation speed allowance specified by the bur manufacturer before selecting a bur.

- Especially, if you intend to use the bur with a turbine, be sure to select one with the right rotation speed allowance.

- Burs with a wider blade such as carbide bur tend to come off easily when cutting load exceeds chuck's holding force.

- Bur also may come off easily when a long type bur is used with a mini head.

- Bur with a worn out shank or chipped blade, and/or crooked bur will tend to come off easily and exert a negative influence on bearing durability.

2. Locking a Bur

-

- Wipe bur shank with clean cloth before inserting to chuck. Debris and other foreign articles that remain inside may cause lower holding force.

- When inserting a bur to turbine, be sure to push it in all the way until the bur stops. Locking insufficient depth is extremely dangerous.

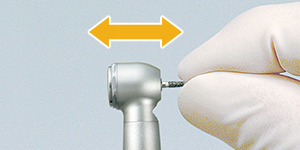

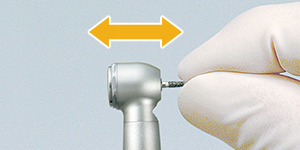

- Make sure bur is tightly and securely locked by giving a pull-and-push test. NSK push-button type chuck used with turbine, is designed to increase the holding force as load increases. By giving a pull-and-push test prior to use, the chuck gains stable holding force from the beginning.

3. When in Use

-

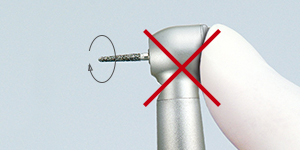

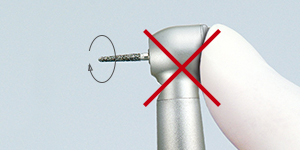

- Don't pull-and-push the push-button when in use